Grade: ADC12 aluminum alloy – widely used in die casting due to its high fluidity and strength. For reference, typical composition: Si 9.6-12.0%, Cu 1.5-3.5%, Mg ≤ 0.30%, Zn ≤ 1.0%, Fe ≤ 0.9% (other trace amounts).

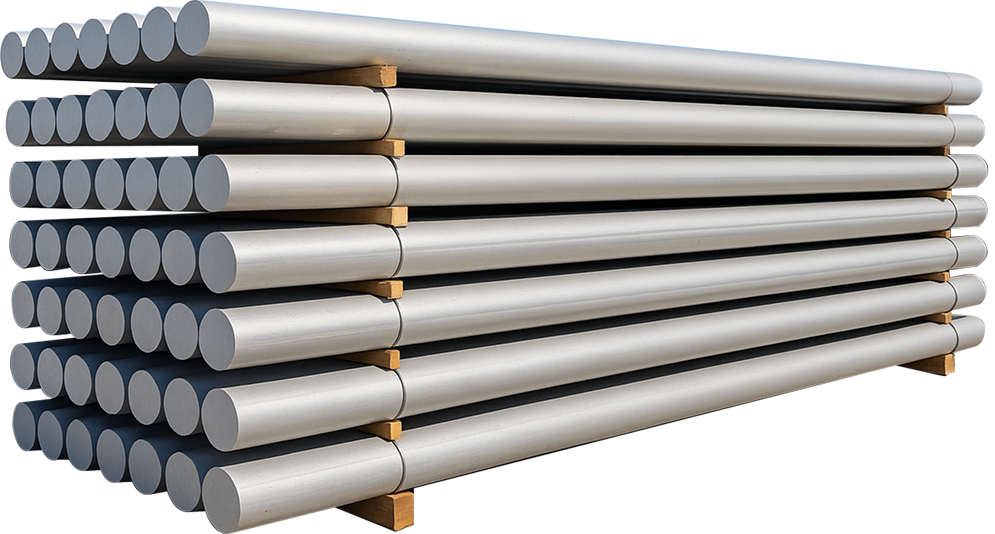

Recognized for their excellent surface finish, corrosion resistance, and formability, 6063 billets are the preferred raw material for producing precision extruded profiles used across architectural, automotive, electrical, and general engineering applications.

Diameter

3.5” – 8”

Length

5800 mm – 7500 mm (customizable)

Finish

Smooth, excellent surface finish

Applications

Windows, doors, curtain walls, pipelines, furniture

Alloy Designation

6063 (Al-Mg-Si series)

Temper Availability

As Cast, T4, T5, T6, or customized on request

Standard Specification

ASTM B221 / EN 573 / EN 755

Length

5800 mm – 7500 mm (customizable)

6063 Aluminium Billets are primarily used for manufacturing:

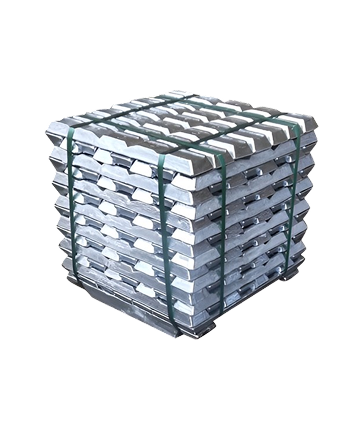

Our cast ingots are an ideal choice for die casting, recycling operations, and custom alloy raw materials, complementing our existing cast billet products.

Grade: ADC12 aluminum alloy – widely used in die casting due to its high fluidity and strength. For reference, typical composition: Si 9.6-12.0%, Cu 1.5-3.5%, Mg ≤ 0.30%, Zn ≤ 1.0%, Fe ≤ 0.9% (other trace amounts).

Applications: Die-casting parts (automotive, electrical appliances), re-melting raw materials, recycled aluminum products, extrusion followed by re-melting, custom alloy production.

Alternatively, the 6 series alloy ingots can be used – these are suitable for applications where different mechanical or corrosion properties are required.

Recycled aluminum can raw material ingots – supporting sustainable production and cost-effective material supply.

Supply format: Standard cast ingots suitable for remelting (e.g., approximately 25 kilograms per piece or larger pieces, packaged in wooden boxes/bundles).

Surface/Surface Treatment: The surface is clean and has a silvery appearance, with minimal presence of impurities. After processing, it can be efficiently melted.

Custom alloy support – We can customize the alloy composition (silicon, copper, magnesium, zinc, trace elements) and the dimensions/weights of the ingots according to the specifications provided by the customer, enabling you to optimize the casting or remelting process.

For information on the complete alloy catalog, custom composition options, minimum order quantities, and shipping details (for use in the United Arab Emirates, the European Union, and the United States), please contact our sales team. Let’s work together to provide you with the appropriate ingot materials for your processes.

Call Now